Dam inspection: rope access professionals on the front line

Chartrain Dam (Rhône, France) was built with huge blue granite stones bound together with a mix of sand and lime. The 70m high and 221m long structure, managed by the local water company, La Roannaise de l'Eau, entered into service in 1892 and requires regular maintenance as well as a thorough inspection every ten years. The last inspection took place in 2015, and rope access professionals from the company Laurent Moretton played an important role.

July 13 2016

Rope access and confined space

A complex work site

Chartrain Dam's ten-year inspection requires surveyors, an engineering firm, divers, and rope access professionals to work closely together. The divers check the waterproof lining underwater above from the dam. Robots hanging from ropes inspect the part of the lining that is above the water. All pipes are inspected. The piping system and submerged part of the dam are verified by robots that take 3D photos. To inspect the exterior wall, La Roannaise de l'Eau contracts rope access professionals from the company Laurent Moretton. Lifelines are installed at the top of the dam for all rope descents. Risk prevention procedures detail every step of the work to be completed, from installing the staging area (locker rooms, restrooms), to organizing access and setting anchors.

Scope of rope access work

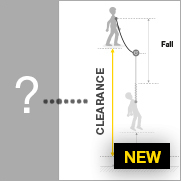

The contracting authority works with rope access professionals since the work is located in an area inaccessible for a basket crane. In addition, the slope of the exterior wall prevents setting up any scaffolding. The first phase of work consisted of understanding the access risks and future rope work. The goal: to install anchor points as intelligently as possible. Next, the rope access professionals were able to conduct the visual inspection followed by a photo report. Any cracks, displaced seals between rocks, calcite, and wear due to vegetation were localized on a grid map. The independent engineering firm analyzed the readings and made recommendations for the work to be done.

Following this diagnostic phase, the rope access professionals started to conduct maintenance work: pulling out the vegetation by hand, burning the roots with a blow torch, cleaning defective seals and then filling them in with sand and lime mortar. Each worker clips tools to the sides of their harnesses and the bucket with mortar on the belay loop. All of their tools are lightweight: trowel, hawk, small hammer, chisel, sponge, and vaporizer. When working, to avoid being weighed down too much, they receive assistance from a colleague who coordinates their needs: preparing tools and equipment, and ensuring that all supplies are ready. From the top of the dam, he coordinates tool use, lowers buckets with small amounts of mortar (3 kilos), and raises empty buckets. At the end of every day a report is written to cite the number of workers needed as well as details on the work completed.

Teamwork

In the rope access profession, working as a pair is fundamental. Two-person teams are the minimum, due to both regulations and the idea that sharing a rope truly encourages teamwork. A rope access professional puts his life in the hands of his partner and complete trust is always necessary. Laurent Moretton, president of the company, is clear, "We have to be able to lower fully trusting the equipment installed by our teammate, to conduct, for example, an emergency rescue. In addition, being organized this way means that the teammates complement each other, since we always pair two people for a project based on the skills and expertise of each."

Petzl, a key part of the solution

Every piece of gear is carefully selected base on simplicity, weight, and efficiency. Petzl's rope access gear perfectly meets these requirements: PARALLEL ropes, the AVAO BOD CROLL FAST harness, removable COEUR BOLT hangers, the compact RIG descender, the ASAP LOCK fall arrest device, the PROGRESS ADJUST lanyard, the ASCENSION ascender, and the PANTIN foot ascender for ascending ropes. Other important equipment includes radios and an ALVEO helmet.

Routine is our worst enemy!

For Laurent Moretton, there is no such thing as a standard work site. "Routine is our worst enemy. Every work site is unique, even though we know this particular dam by heart. The risks associated with being so high up require us to think about every detail of the work site on a daily basis, asking ourselves, 'How can we best go about equipping this site?' This is more than essential. During our regular meetings, we analyze each work session. I often tell my rope access workers, 'be careful.' This might seem a bit silly, but it's important. We work in a high-risk profession, and we need to constantly evaluate and limit the danger. Training courses, work site layouts, and risk prevention plans are all helpful of course, but we are the ones out there at the site, and we have an obligation to constantly analyze what we do."

Laurent Moretton: a work-at-height company in Saint Symphorien sur Coise (Rhône, France)

Laurent Moretton founded his company in 2005, after working for twelve years as a salaried rope access professional and in business development. The company specializes in urban and industry projects, and has eight rope access professionals from 22 to 33 years old. Their professions include: masonry, painting, and roofing.

Laurent Moretton started out as an arborist as a twenty year old, and then became a rope access professional after meeting several cavers and high-mountain guides. With twenty-three years experience working in the profession, Laurent is still just as excited about rope access.

Link: www.moretton.fr

Related News