The Rion Antirion Bridge in Greece inspected and maintained by Hydrokarst

Located in Greece, the Rion Antirion Bridge is considered a masterpiece of technology and engineering. It connects the Peloponnesus to mainland Greece. To ensure it remains intact, the French company Hydrokarst conducts inspection and maintenance on this cable-stayed bridge. Learn more about how this team of rope-access professionals coordinates operations at this truly extraordinary work site.

December 16 2016

Rope access and confined space

A cable-stayed bridge is a structure where the cables support the bridge deck and the towers support the cables. Illustration using the Rion Antirion Bridge.

An exceptional bridge

The Rion Antirion Bridge is a cable-stayed bridge located in Greece's Gulf of Corinth. Built in just 5 years, it has become a vital artery connecting the Peloponnesus to mainland Greece since its completion in 2004. Prior to construction, crossing the gulf by ferry took 45 minutes. Today, thanks to the bridge, it takes only 5 minutes to make the crossing.

2.8 kilometers long, the structure consists of a main 2252 meter long cable-stayed bridge connected by viaduct at each end: one to the city of Rion, and the other to the city of Antirion. It is the third longest cable-stayed bridge in the world behind the Millau Viaduct (France) and Jia-Shao Bridge (China).

Tower heights for the Rion Antirion Bridge

Unique constraints

The Rion Antirion Bridge is considered a masterpiece, having successfully overcome several technological challenges. Designers and builders had to take into consideration the Gulf of Corinth's numerous natural constraints. The bridge has to:

- connect two active tectonic plates (the Peloponnesus and continental Greece) that are moving away from each other by several millimeters per year,

- withstand strong winds up to 180 km/hr,

- withstand earthquakes up to 7.0 on the Richter scale,

- cross over a body of water that is 65 meters deep at its deepest point.

Hydrokarst commissioned to conduct bridge inspection and maintenance

Created in 1977 and based in Sassenage, France, this French company has years of experience and a unique expertise in complex and difficult-access work. It specializes in four main professions: rope access, diving, confined spaces, and hydromechanics. The company has 240 employees; 60% of its work sites are in France and 40% in other countries. Work includes protecting roads against landslides, works of art, dams, and port infrastructure.

Due to a problem with one of the towers, the bridge management authority first contacted Hydrokarst in 2005 (the company that supplied the tower, Freyssinet, is one of Hydrokarst's longtime partners). Since then, Hydrokarst has been the officially appointed company to conduct inspections and maintenance on the bridge for sections that are difficult to access. The bridge management authority contractually guarantees Hydrokarst a minimum two months of work per year.

Primary work phases

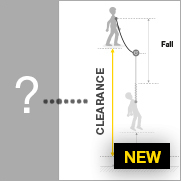

Bridge inspection and maintenance require two to three months of work for a team of three to six rope access technicians trained in civil engineering inspection and reporting. Hydrokarst inspects those sections of the bridge only accessisble by rope: the piers, towers, and cables. Each of these bridge components requires a thorough inspection.

A Hydrokarst rope-access professional inspecting concrete beneath the deck.

First is the concrete. Bad weather and exposure to the salty air can degrade or damage certain sections of concrete. Visual inspection serves to pinpoint those areas with surface damage as well as to identify any sections that may potentially be subject to harsh climatic conditions in order to prevent any future damage.

Cable inspection by Hydrokarst rope-access technicians

The bridge's size and technical complexity are the defining characteristics of this work site. One more challenge adds to the complexity: all inspection and maintenance operations are conducted while the road is still open; closing a lane is a rare occurrence.

Focus on bridge inspection and maintenance techniques

For all rope access work, the Hydrokarst team uses typical rope access equipment as well as guide-pulleys for the cables and a rescue winch for raising personnel after working on the overhanging section of a pier. They also use very specific techniques:

To work on the towers and cables, the team uses an elevator and a caged ladder inside the tower to reach the top from the bridge deck, and then lowers down the outside of the tower by rope.

From left to right: working on the cables; at the top of one of the bridge towers.

For work underneath the deck, the team lowers by rope from the deck, using intermediate anchors, all the way to the sea surface and sometimes even below to work inside the piers. They climb back up by using stairs inside the piers.

Rope access technicians working underneath the deck.

Bonus photos

Included in this article

Related News