A wine cellar unlike any other

Professionals may have their daily routine, but there are definitely those projects that stand out head and shoulders above the rest for their originality. The company Besson Michel worked on one of these projects, digging a wine cellar designed specifically for only the most prestigious vintages. Of course, Petzl also played an important role by lighting up the way for the team who led this truly extraordinary dig.

April 29 2019

Explosive atmosphere

What is Besson Michel’s primary field of expertise? What type of work does the company typically do?

Our company was founded in 1984 and specializes in blasting and setting explosives in complex environments. At the start, we did controlled blasting to level terrain in delicate situations (cities, near buildings, bridges, gas lines, etc.), as well as demolitions in urban environments (water towers, chimneys, dams, bridges, etc.).

Then, clients such as hydroelectric dam operators or caves and caverns open to sightseeing started to ask us to blast penstocks and access tunnels. This type of work requires a lot of precision to avoid damaging or even destroying the site due to poor blast design.

Who works for you, what type of training and education does your staff have, and what are their specific skills?

Our company has a small team of two or three people who specialize in blasting and operating mining equipment (drilling rigs, excavators). For major work sites, we contract with seven additional specialists who have been working with us for years. These are independent subcontractors or temps with an expertise in drilling, bulldozing, or land leveling. All have top-notch skills in blasting, drilling, and operating heavy machinery; an expertise gained after working at so many different work and construction sites, with training and tutelage provided by the company manager.

Digging this wine cellar proved to be an extraordinary project. What were the specific constraints involved?

The work consisted of digging a 2.5 meter diameter main tunnel and several side chambers for an underground wine cellar. For this specific project, our client requested the utmost discretion and to remain anonymous, so we cannot reveal the location or their name other than the fact that this is for a prestigious vintage!

This project proved unique for us; no explosives were used due to the soft rock. We always love this kind of challenge! For the second time in the company’s history we used only mechanical means to excavate. We mounted a milling cutter onto a radio-controlled electric robot and a road heading machine to bore the tunnel. This required us to train three operators on how to use the equipment. And then, to make the work just a little “spicier,” there were thin layers of silica in the rock, which meant that the robot operators had to wear positive pressure breathing masks to protect their lungs.

In terms of lighting, what do you usually need, especially when working underground?

As with any tunnel, we always set up a fixed lighting system using LED spotlights (which have replaced the classic and fragile halogen lamps that use a lot of energy). For individual safety, everyone uses a helmet equipped with enough individual lighting power to work efficiently (whereas before, we only needed enough lighting to be able to exit the tunnel if the spotlights stopped working). I remember our first underground worksite in 1985: we picked up a set of old mining headlamps where we wore the battery pack on our waist belts. It was a heavy, cumbersome system, with a very limited battery life.

After that, we used a few of Petzl’s original caving headlamps equipped with a 4.5 V battery. At any given worksite, we needed to have an ample supply of spare batteries and small light bulbs, which blew out from time to time. However, using these headlamps represented forward progress for our team.

Today, how do Petzl headlamps help you in your work?

Today, we use Petzl LED headlamps with rechargeable batteries. These headlamps offer four main benefits:

- They are very bright, which means considerable energy savings for our overall lighting system since we can see what we need within the immediate vicinity of our workspace (up to three meters) when using the wide beam, and see where we are walking as we move around through the tunnel, adding a measure of safety for everyone.

- They are equipped with a long-lasting rechargeable battery in which a single charge lasts for a full eight-hour shift, and sometimes even longer depending on the brightness level used. We have two batteries per headlamp so that there is always a fully-charged battery at hand. However, by systematically charging the battery at the end of shift, we have noticed that a second battery is more of a luxury than an real necessity.

- One of the clear advantages of Petzl headlamps is the huge on/off selector button, which is easy to turn even when wearing gloves. This is an important feature for the types of worksites where we operate.

- They are incredibly robust! Even though everyone we work with takes care of their gear, stuff gets dropped from time to time. Helmets equipped with a headlamp have fallen from over two meters up with barely a scratch. Their watertight design has also been put to the test and Petzl headlamps perform brilliantly: in tunnels we sometimes encounter underground water tables or have to use pressurized water for digging.

While digging this particular wine cellar, we also used the DUO headlamp’s FACE2FACE feature for the first time, which allowed us to leave our headlamps on when talking to colleagues without blinding each other. This proved a real eye-opener in terms of visual comfort, especially in situations where the site manager needs to explain a document to staff or when training a new team member.

Lighting considerations in an explosive environment

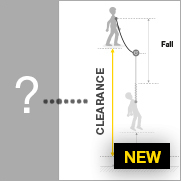

When the risk of an explosion exists in a given environment, the dangerous areas are designated as risk zones based on the amount and types of combustibles, gases, or dust. Any equipment used in these areas, especially lighting equipment, must comply with current regulations.

European regulations define six risk zones (Zones 0, 1, and 2 for gases, and Zones 20, 21, and 22 for dust) that are well known but worth explaining in greater detail. The atmosphere for zones 0 and 20, saturated with certain types of gases and/or dust, prohibits humans from entering the zone and requires complete ventilation before any work can begin. Once the saturation levels have been reduced to the same level of risk defined for zones 1, 21, 2, and 22, it is possible to start working. This requires using the right equipment, and Petzl’s DUO and PIXA headlamps comply with current regulations.

However, in any zone with an established probability of risk, professionals need to learn what types of gases and dust are involved and how their headlamps handle the associated risks. The markings on your product will define the zones, gases, and types of dust where your headlamp can safely operate: this is essential information to consider when choosing a headlamp.

| Read the full article |

Included in this article

Related News