Connecting the MGO to a structure

As with all connectors, the MGOs are made to be loaded on their major axis and are weaker when poorly positioned.

Warnings

- Carefully read the Instructions for Use used in this technical advice before consulting the advice itself. You must have already read and understood the information in the Instructions for Use to be able to understand this supplementary information.

- Mastering these techniques requires specific training. Work with a professional to confirm your ability to perform these techniques safely and independently before attempting them unsupervised.

- We provide examples of techniques related to your activity. There may be others that we do not describe here.

1. Common examples of wrong positioning

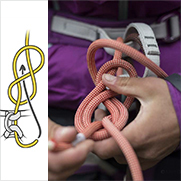

Open gate loading

Risk of the MGO disconnecting

Multidirectional loading:

Variable strength loss depending on the angle between the axes of loading.

Risks of rubbing on the gate and the release lever:

Risk of the gate opening and of the MGO disconnecting.

Frontal pressure on the gate:

The resistance to frontal pressure on the gate is greater than 1 kN for the CE versions and greater than 16 kN for the ANSI versions.

Lateral pressure on the gate:

The resistance to lateral pressure on the gate is greater than 1 kN for the CE versions and greater than 16 kN for the ANSI versions.

Attachment to an anchor that is too small:

The length of the MGO can create a significant cantilever load with a risk of breaking the MGO or loosening the anchor.

Medium width BAT'INOX-type anchors:

This type of anchor almost allows the MGO 60 to move freely, but is tight enough to create a cantilever load in certain cases (e.g. if the user climbs above the anchor and falls).

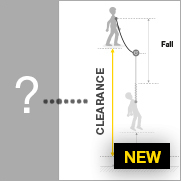

2. Cantilever load over an edge

In a work situation, attaching an MGO to an upright is a common necessity. This can create a cantilever load over an edge.

In this position, the MGO must be used with precautions:

- beware of the user's position relative to the anchor

- With a Y-lanyard be sure to connect both MGO to the anchor