Everything You Need to Know About Inspecting and Maintaining Your Helmet

July 7 2022

Rope access and confined space

Indispensable for all work-at-height professionals, the helmet is one of the most important pieces of Personal Protective Equipment. It provides protection from falling objects, as well as if the user falls.

Like all PPE (Personal Protective Equipment), the helmet is subject to regulation requiring periodic inspection, so you can make sure the helmet is still in suitable condition to protect the user. In this video, Nate Williams from the Petzl Technical Institute in Salt Lake City, Utah, will go over the inspection procedures required for Petzl VERTEX and STRATO helmets. He'll use the STRATO and VERTEX VENT to demonstrate. To complement this video, download the Inspection Procedure document from the VERTEX and STRATO product pages on our website. This will provide a step-by-step guide for completing your inspection.

HOW TO INSPECT A VERTEX AND STRATO HELMET

The Petzl VERTEX and STRATO helmets come with modular and replaceable components. This means that the user can replace both the headband and chinstrap. In the second video, Keith Luscinski from the Petzl Technical Institute in Salt Lake City, Utah will explain the proper procedure for replacing the headband and DUAL chinstrap on your helmet. Note that the DUAL chinstrap allows the worker to modify the strength of the strap to adapt the helmet to different work environments: working at height (EN 12492) and working on the ground (EN 397).

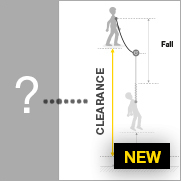

Adjust the strength of the chinstrap for different environments:

- Higher strength to limit the risk of losing the helmet during a fall (strength greater than 50 daN)

- Lower strength to limit the risk of strangulation, in the event that the chinstrap catches on something when the worker is on the ground (strength less than 25 daN)

HOW TO REPLACE THE CHINSTRAP AND HEADBAND ON A VERTEX AND STRATO HELMET