How To Inspect Your Rope

One of the most surprisingly difficult pieces of PPE to inspect are ropes.

March 6 2020

Rope access and confined space

Nathan Williams, PTI Trainer and Head Instructor of Petzl’s Personal Protective Equipment Inspection course says that, “ropes, in particular, can sometimes provide obvious signs to the inspector that the rope is not fit for service. However, ropes can also be very tricky to inspect and a decision on whether or not to leave a rope in service or remove it from use can not be so easy to identify.”

Whether you are using the 12.5mm low-stretch kernmantle CONTROL rope to move in trees, or the 12.5mm high-strength VECTOR rope for technical rescue, all inspection procedures are the same and should be done regularly.

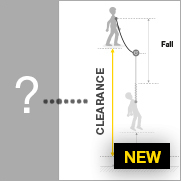

Any user of the equipment should be trained in basic daily pre-use inspection. Anyone responsible for equipment management is required to know the full history of gear prior to inspection, precise information on the usage conditions and all notable events. Falls, extreme temperatures or any modifications made to the gear is considered a notable event.

The first step in determining if your rope is acceptable for use is to look at the serial number. All ropes have a serial number located on the rope and, depending on the year of the rope, will have a specific code.

After identifying the year of manufacture, make sure that the product lifetime has not been exceeded. All textile and plastic goods have a lifetime of 10 years.

If there is no obvious serial number on the rope, there is another option. For dynamic ropes, there is a marking thread in the rope’s core. The thread color denotes the year of manufacture.

For semi-static ropes, there is a marking tape in the rope’s core. The tape shows the rope’s year of manufacture.

Once the date is confirmed and the rope is not older than 10 years, you can begin to check the condition of the sheath. Make sure there are no cuts, burns, frayed strands, fuzzy areas or signs of chemicals.

If the sheath passes inspection, begin to check the condition of the core with a tactile inspection over the full length of the rope. Pay attention to hard spots, swelling, soft or crushed areas. These are signs that the rope needs to be retired.

Next, check the plastic sheaths for wear or cuts, and the sewn terminations and safety stitching on both sides for loose, worn, or cut stitches.

Petzl recommends an inspection at least every 12 months, but your intensity of use and any exceptional event in the life of the product may cause you to inspect your PPE more frequently. The person responsible for equipment management and inspection must be trained as a competent person in PPE inspection and should reference Petzl’s technical information, which is available on all Petzl products.

For more information on PPE Inspection courses at Petzl America in Salt Lake City, UT visit PetzlSolutions.com.

Technical information for ropes

PPE Inspection Procedure

PPE Checklist

Tips For Maintaining Your Rope

Related News