Smaller Diameter? What's The Catch?

What if smaller ropes and different hardware offer more than just a lightweight option? Petzl spoke with experts across the country to ask why the switch to 11mm ropes and T-rated hardware might offer more benefits than you might think.

November 29 2022

Technical rescue

For decades, fire departments have been dedicated to NFPA G-rated equipment. Using specific gear because of tradition, comfort and “this is the way we do it because this is the way we’ve always done it,” is a common practice and belief. But, what if smaller ropes and different hardware offer more than just a lightweight option? Petzl spoke with experts across the country to ask why the switch to 11mm ropes and T-rated hardware might offer more benefits than you might think.

Russell McCullar - Senior Instructor at Mississippi State Fire Academy

McCullar’s name rings nationwide as a rope rescuer, researcher, teacher and “forever student.” He manages NFPA 1006 rescue programs and serves as a rescue specialist and technical search specialist with FEMA’s Tennessee Task Force 1. McCullar instructs other rescuers around the country, consults with his company Craft Rescue, and volunteers as an instructor for the National Cave Rescue Commission.

I know you’ve presented on the history of rope rescue many times, but can you explain briefly when and why departments first started using half inch ropes? Why have they always been the standard for departments?

The shift to a standard strength for rope and hardware was a direct result of the FDNY LODDs (line of duty deaths) in 1980. In the 80's and 90's there was limited data on rope strength and degradation after use, shock loading and exposure to UV and chemicals. The industry held rigidly to a theoretical 15:1 SSSF (static system safety factor) and 9,000 lb MBS (minimum breaking strength) for raw components such as connectors and ropes. The caving, climbing and mountain rescue communities were on the forefront of rescue technology and limitations. These groups needed lighter equipment for their expedition style of backcountry and below ground rescue and utilized gear that was considered sport or recreational. Fire departments that played in both the urban industrial and backcountry were among the early adopters of lighter and smaller equipment. Demands of the backcountry necessitated lighter gear and longer ropes. Alongside those first adopters were departments who were listening annually at ITRS (International Technical Rescue Symposium).

Is this change due to T-rated gear in general, or was it spurred by the lighter ropes? What came first?

The biggest shift we’re seeing in the market is due to changes in technology and marketing. Early G-Rated ropes were larger than ½” or 12.5mm, in fact it was often ¾” diameter. Technology and rope engineering continues to improve and greater strengths can be found in smaller sizes. In 2022, I would speculate that among those making the switch to 11mm solutions, 70 percent are following marketing and 30 percent are truly embracing force limiting concepts.. Of the adopters of smaller size and weight systems; most still value quality manufacturing and third party testing so they landed on T-rated gear, but not exclusively. Everyone wants lighter gear and a 300 foot rope in a 200 foot rope bag. However, there are still many who are not yet comfortable letting go of the high strengths and SSSFs of old.

What are some benefits of 11mm rope?

An 11mm rope has a better hand and knotability. You can fit about 50 percent more in the same space of a rope bag. In our 2014 tests with 400 plus pull tests, we observed a statistically significant trend that 11mm rope statically performed better in most devices. In many instances it costs less, definitely weighs less, requires less raw material and, in turn, has a greener footprint.

I’ve heard that “the only reason manufacturers are still making G-rated equipment is for fire departments.” What are your thoughts on this?

Manufacturers have to listen to the customers. Firefighters are the biggest rescue customer in North America, with about 1 million firefighters across 27,000 fire departments in the United States. Approximately one-third are paid and the rest are volunteers. The fire service was steeped and educated in 15:1 and 9,000 lbs for over 20 years. It’s taking time to reeducate older and younger generations on the way research and technology has changed the landscape. This is an area I've dedicated much time to with fire academies and rescue trainers. This is the faucet from which most of the knowledge flows to future generations. It’s also where we’re making headway on the T-Rated switch.

What’s your advice on encouraging FD’s to make the switch?

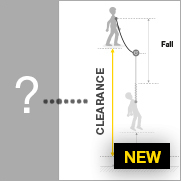

I'd rather have a great 35kN rope over a crummy 40kN rope. Desirable properties in a rescue rope include good hand, low stretch, the ability to stay 'round,’ abrasion resistance and minimal sheathe over core slip. Some of the early 11mm G- ropes had raw strength, but scored very low in the areas above. Raw static strength over 30 kN is irrelevant in modern force-limiting rope systems. As an industry, we know our MAF (maximum arrest force) on two person loads is 6 to 12 kN or 1,350- 2,700 lbs, 99 percent of the time. You’d be hard pressed to generate more force than this. OSHA, ANSI and SPRAT allow for components and anchorages that are two times the MAF. The industry standard on aluminum connectors is 27 kN or more, rope 30 kN or more and pulleys 36 kN. Any strength above 30 kN is almost certainly wasted.

When building out a system, I advise the following:

- Use components from quality, ISO 9001 certified manufacturer

- Use components that are 2x the MAF

- As long as the rope is 30kN, put more emphasis on the mentioned above characteristics of a quality rope

- Mainline devices should be intuitive with high pulley efficiency, and resist operator error.

- Belays should resist most operators' errors and nothing does this better than an ASAP w/ ASAP’SORBER AXESS.

- When employing TTRS- use a rope tailer(s)

Nick Herzog - Captain West Valley City Fire, West Valley, Utah

Nick has been with the West Valley Fire for 15 years and Captain for about four years. He’s also part of the Technical Rescue program where he assists with training and equipment ordering.

Why did you make the switch?

We’ve used the 12.5mm since I’ve been with the department because it was always just an industry standard. It was easy because all the hardware we used on a call was compatible with each other, and I could build onto a system that a neighboring department had started. But, then other departments around the valley started to use 11mm. For instance, Sandy, a city just 20 miles south of us, performs a lot of rescues in the canyons; and so for them it’s easier to carry the lighter 11mm rope. So, then some of us had 12.5 some had 11, and the hardware wasn’t compatible anymore and we couldn’t easily attach to systems. Ultimately, we needed new rope so I transitioned West Valley Fire to 11mm. We were also updating our techniques; like moving to a twin tension system, which is easier with a smaller rope.

What made you hesitant at first?

Only thing I’d be hesitant with is the old school thought that the 12.5mm is always the standard and has the built in safety factor of 15:1. In the fire service there's a way of “this is the way we do it because this is the way we’ve always done it,” so it can be hard to move away from that.

What has been easier since the switch?

Honestly, it’s been such a short time since the switch. But, feedback from the other crews is that it’s easier to tie knots, easier to handle, and it’s more pliable.

Advice to teams who’re thinking about using 11mm?

Research the new technology and if the newer techniques work for your department then make the switch because smaller ropes are a whole lot easier to work with. With the switch though, you will have to buy new hardware. But, if you’re ordering new equipment anyways, then look into it.

Steve Crandall - Technical Rescue Team Captain

Steve is currently a captain and team coordinator at SLCFD Heavy Rescue 1 in downtown Salt Lake City, UT. He has served there for more than three decades. During that time, he has also been a Rescue Team Manager, rescue specialist, and heavy rigger for Utah’s FEMA/USAR Task Force 1, Before transitioning to a full time rescuer, he was team leader of the mountain rescue group for a volunteer backcountry SAR team. He is owner and lead instructor for Heavy Rescue Training LLC, delivering technical rescue training to fire service, backcountry SAR, industrial, and military teams. Steve also is an assistant instructor for Ropes That Rescue out of Sedona, AZ. He’s also written several technical rope rescue manuals.

When did you make the switch to 11mm ropes?

Our Fire Department team made the switch more than a decade ago. Well, the way I look at it is that NFPA is a consensus standard, it’s not law. NFPA 1983 was written for manufacturers and testing, not for end users.

Why did you make the switch?

I was lucky enough to be the guy in charge and that made the decision to switch easier. Personally, coming from the climbing and backcountry rescue world, it just made more sense. Most of the team were from a climbing background already too, so we were used to using 10.5mm, REVERSO, GRIGRI, etc. on our days off rock and ice climbing. Financially it was a little tricky, and took us about a year and a half split over two budget years. But, we started building a light backcountry kit to service the foothills that surround our city and for tower and crane rescue. Then, as time went on we transitioned everything over.

Why would teams be hesitant to switch?

Tradition; and people might misunderstand the standard and believe it’s an end user standard when it’s not. Or they may mistakenly believe that it somehow dictates an operational safety margin of 15:1, which it doesn’t. There’s always the “safety first” mantra, and people might equate safety with strength and ratings, and that’s not necessarily true. And, in many ways changing over may be cost prohibitive. Teams have spent tens of thousands of dollars on equipment already, and to refit everything is expensive. That’s a big ask of a team that is funded by public money with a strict budget.

Advice to teams who’re thinking about using 11mm?

If the decision is based on safety factors, then I think perhaps they should critically analyze what that safety factor is, or should be for their own team, and why they need it. Because you can easily reduce safety factors well below what people believe is a “standard." Some people may think it's OK to trade equipment for knowledge, time and skill. They may say, "Oh, if we just buy this device that does these three different things, we don't need to learn how to do this or that particular technique because the tool will do it for us or we don’t need to spend as much of our time training because we use fat ropes and steel hardware which all allow for big margins of error.” That’s not a mantra that our team ever really embraced; we’ve always wanted to do more with less, use lighter over heavier and move faster rather than slower. For us, knowledge and education really dictates our operation safety and efficiency, not equipment ratings. Arnor Larson said, “Knowledge is light in the rucksack and not easily left behind.” So if your rucksack is lighter, you can move faster. If you can move faster, you can get the rescue done quicker, and if you can get the rescue done quicker, you can get that trapped or injured person to safety and definitive medical care sooner. In the end, I think that’s why most of us became rescuers in the first place; so we could help people and get them back to their family safely in the most efficient and effective way possible on the worst day of their life. And for me and my team, that means 11mm ropes (or smaller) and lighter weight hardware.

Related News